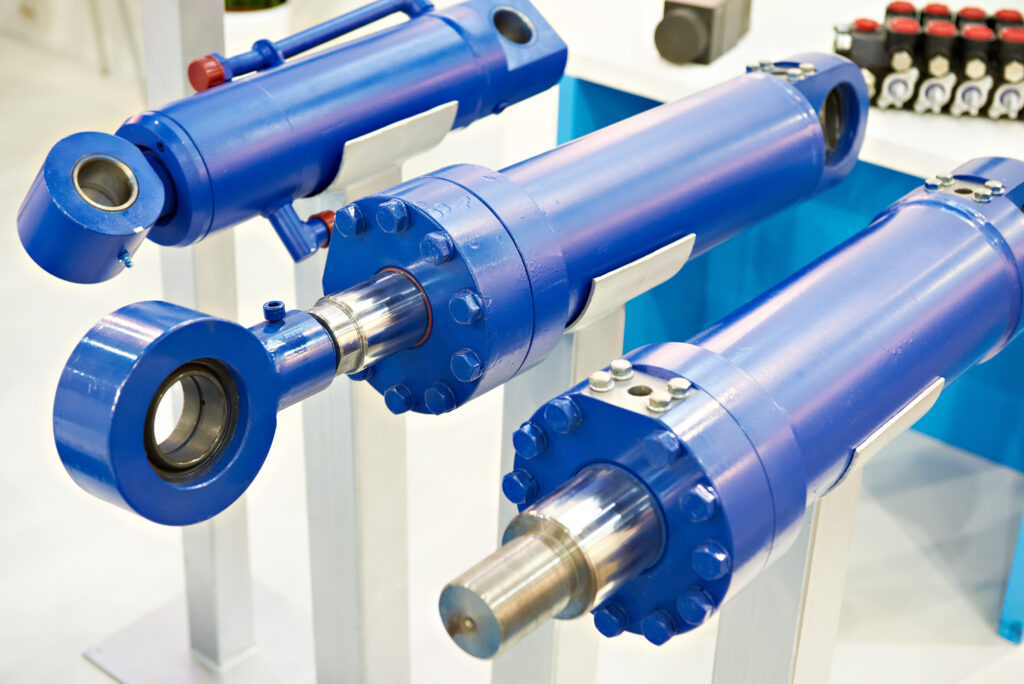

Hydraulic cylinders come in a variety of designs and constructions depending on their intended application. Pressurized hydraulic fluid is used to power the linear action of the cylinders, allowing them to act like ‘muscles’ — extending, contracting, and locking. Cylinders consist of a cylinder barrel with a cylinder bottom (or “cap end”) sealing off one side and a cylinder head on the other, where the piston rod protrudes from the barrel. The multiple types of cylinders use different methods to attach the end caps to the cylinder barrel, along with other internal differences including material, operating pressure, wall thickness, and more.

Three of the most common types of hydraulic cylinder are tie-rod, welded body, and telescopic. All of these cylinders can be either single- or double-acting. Single-acting cylinders are the most simple type. Hydraulic force can only be applied in one direction from the single port, with the opposite action accomplished by gravity or a return spring. Double-acting cylinders are capable of using hydraulic flow to to extend and retract the plunger, providing faster and more controlled movement. Double-acting cylinders are more common than single-acting. They contain two connection ports and require a compatible pump in order to provide hydraulic flow in two directions. Double-acting cylinders are useful in situations requiring push/pull forces with repeatable accuracy.

Tie-Rod Hydraulic Cylinder

Tie-Rod cylinders use threaded steel rods to hold the end caps to either end of the cylinder barrel. Smaller bore cylinders usually have 4 tie-rods, while larger bore cylinders may require as many as 20 tie-rods to withstand the forces being produced. Tie-rod hydraulic cylinders are standardized by the National Fluid Power Association (NFPA) and as a result, cylinders are interchangeable between manufacturers with the same mountings. Tie-Rod cylinders are most often used in industrial factory and heavy-duty manufacturing applications.

Welded Body Hydraulic Cylinder

Welded Body cylinders have no tie rod. Instead, everything is welded together: the barrel to the end caps, the ports to the barrel, and the front rod gland is either bolted or threaded, which allows the piston rod assembly and seals to be removed for service. When compared to tie-rod cylinders, welded body cylinders have a few advantages. Welded cylinders are narrower and shorter, making them ideal for fitting into machinery. Welded cylinders are also do not have to worry about failure from tie-rod stretch as a result of high pressure and long strokes. They are also easily customizable, as special ports, mounts, and valve manifolds may be added. As a result of their welded construction, they can be harder to service in the field than tie-rod cylinders. Welded body hydraulic cylinders are used in the construction/heavy equipment industries, material handling/lift truck, and off-highway & mining applications.

Telescopic Hydraulic Cylinder

Telescopic hydraulic cylinders consist of nesting piston rods and barrels in order to provide extended stroke. The piston rod also acts as a piston barrel, containing another narrower rod within. These progressively smaller rods sit within each other when retracted and allow the rods to extend further than just a single length of a cylinder. Compared to a normal “single” stage rod cylinders, telescopic cylinders can consist of up to 6 stages. They are more costly than welded body or tie-rod cylinders and are typically single-acting. Double-acting telescopic hydraulic cylinders must be custom designed and manufactured to required specifications. Telescopic cylinders are typically used in specific use cases, though they can be most commonly found on the dump beds of trucks and trailers.

Hydraulic Cylinders and Parts at Iron Wing Sales

Looking for replacement parts? Iron Wing Sales has a large inventory of Hydraulic parts, including cylinders, pumps, motors, seals, and more. All of our parts are In-Stock and Ready-to-Ship. Search our inventory by part #, category, or manufacturer. For further assistance, contact us at: sales@ironwingsales.com or 216-912-9089.