Hydraulic pumps are devices that convert mechanical energy into hydraulic energy and are used in a wide range of industrial, agricultural and construction applications. They play a crucial role in controlling the pressure and flow of hydraulic fluid, which is used to power machines and systems that require high levels of force and motion.

There are three main types of hydraulic pumps: gear, piston, and vane. Each type of pump works differently, and each has its own set of advantages and disadvantages. While there are other, more specified types of pumps, this post will be broadly discussing the functions and uses of these three main types.

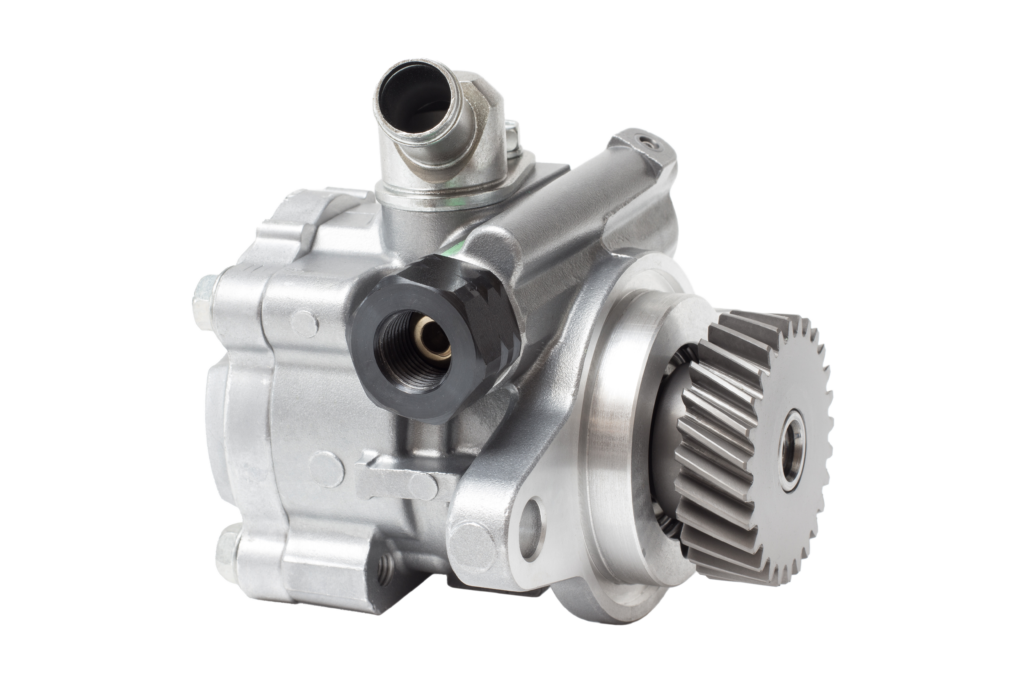

Gear Pumps:

Gear pumps are simple and reliable devices that consist of two rotating gears that mesh together, creating a sealed chamber. As the gears rotate, they draw fluid into the chamber and then force it out through the outlet, generating pressure and flow. Gear pumps are typically used in low to medium pressure applications and are ideal for applications where low noise and vibration are important.

Gear pumps are typically the most inexpensive and have fewest moving parts of the pumps mentioned in this post. Gear pumps are fixed displacement (rather than variable displacement) and are usually used in open center hydraulic systems. A gear pump’s performance is rated in terms of its maximum pressure rating, cubic inch displacement and maximum input speed limitation.

Piston Pumps:

Piston pumps are more complex than gear pumps and consist of a series of reciprocating pistons that are driven by a crankshaft. As the pistons move back and forth, they create a series of alternating pressure and vacuum cycles, which draw fluid into the pump and then force it out. Piston pumps are capable of generating high levels of pressure and are ideal for applications that require high flow rates, such as in construction machinery.

Piston pumps can be either fixed or variable displacement, depending on application. Piston pumps have higher initial cost than gear pumps, but are able to withstand higher pressures at the same displacement. They are among the most efficient hydraulic pumps, offering efficiencies of over 90%.

Vane Pumps:

Vane pumps are radial devices that consist of a rotating cylinder and a number of vanes that slide in and out of slots in the cylinder. As the cylinder rotates, the vanes are forced outwards, creating a sealed chamber. Fluid is drawn into the chamber and then forced out, generating pressure and flow. Vane pumps are often used in applications where low noise, low vibration, and precise control of flow are important, such as in mobile equipment.

Conclusion

Hydraulic pumps are essential components in hydraulic systems and are used to generate pressure and flow in a variety of applications. The choice of hydraulic pump will depend on the specific requirements of the application, such as cost, vibrational and noise tolerances, as well as pressure and flow requirements. The right pump can make a significant difference in the performance and efficiency of a hydraulic system.

Hydraulic Pumps at Iron Wing Sales

Looking for replacement hydraulic parts? Iron Wing Sales has a large inventory of Hydraulic parts, including pumps, cylinders, motors, seals, and more. All of our parts are In-Stock and Ready-to-Ship in order to help minimize downtime. Search our inventory by part #, category, or manufacturer to find the parts you need. For further assistance, contact us at: sales@ironwingsales.com or 216-912-9089.